LFR Guide Bearing

LFR series guide roller bearings are the most widely used and economical products in linear guide rollers, which can be adapted to cylindrical guide rails, with smooth running, small errors, very low running noise and very high running speed. They are widely used in embroidery machines, linear guides, industrial robots, automation equipment, cutting equipment, mobile guides, production lines, transmission machinery, medical instruments, printing machinery and other CNC equipment.

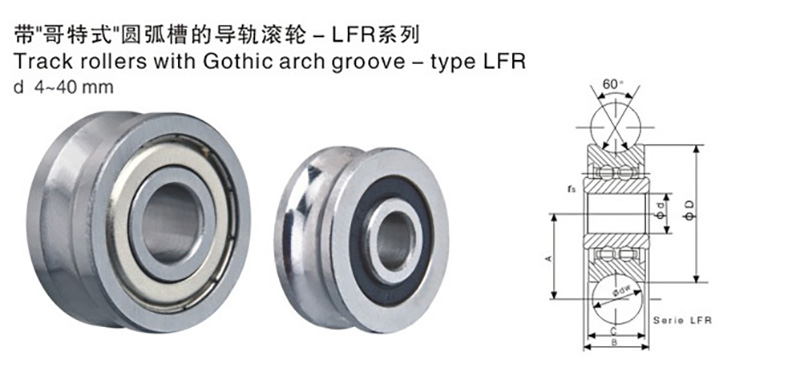

The contact between the roller and the guide is 60 degree contact at two points, which has good contact performance and low running resistance, thus achieving a long service life.

The roller adopts the internal structure design of double-row angular contact ball bearing and thickened outer ring, so that the roller has a higher bearing capacity, and the roller bearing is equipped with eccentric wheel and concentric shaft after simple installation.

The rollers are made of high quality bearing steel or stainless steel, heat treated, precision ground and machined, and filled with long life high quality multi-purpose grease. The rollers are protected from dust by metal dust caps (KDD) or rubber seals (NPP).

Features

- Guide roller bearings are mainly made of high quality bearing steel (GCR15) or stainless steel (AISI440C \ 420), after heat treatment with good mechanical properties, and the use of precision steel balls to further enhance product performance. Cages made of engineering plastic or high quality Nissan steel with SPCC also guarantee reliable operation of the bearings. The rollers are fitted as standard with SHELL high quality multi-purpose grease, nitrile seals or dust caps made from high quality Nissan steel tape SPCC, ensuring good lubrication and sealing against dust during operation. In order to adapt to different applications, we can also customise the roller with different greases, seals made of different materials, seals made of high temperature resistant fluoroelastomer, etc.

- High permissible speed, low resistance and long life

The surface of the outer ring of the LFR series guide roller is designed in a Gothic shape, so that when the roller works, the roller and the guide form a two-point contact at an angle of 60 degrees, with low frictional resistance and uniform load, avoiding stress concentration and boundary effects caused by installation and manufacturing errors in the work of the roller, so that the guide system has the working characteristics of high speed, low energy consumption and long life. - Simple and convenient installation

Guide roller bearing configuration eccentric axis and concentric axis, so that the installation is very convenient, adjust the eccentric guide roller bearing eccentric amount can get the right preload. - Smooth running, small error, very low noise operation

Special processing equipment and testing equipment to ensure the accuracy of the roller shape, mature processing technology and strict quality inspection process to make all the roller outer ring radial runout and work surface true roundness is good, so that the guide system in the operation of the error is very small, smooth running, running noise is very low.

| Bearing the code | Weight(g) | Main dimensions(mm) | Load | ||||||||

| dw | d | D | C | B | A | rs | Cw(KN) | Cow(KN) | Frperm(KN) | ||

| LFR50/4NPP | 3.5 | 5 | 4 | 13 | 6 | 7 | 8.04 | 0.2 | 1.05 | 0.85 | 1.15 |

| LFR50/5-4KDD | 7.5 | 4 | 5 | 16 | 7 | 8 | 9 | 0.2 | 1.2 | 0.86 | 1.3 |

| LFR50/5-4NPP | 7.5 | 4 | 5 | 16 | 7 | 8 | 9 | 0.2 | 1.2 | 0.86 | 1.3 |

| LFR50/5KDD | 8 | 6 | 5 | 17 | 7 | 8 | 10.5 | 0.2 | 1.27 | 0.82 | 1.3 |

| LFR50/5NPP | 8 | 6 | 5 | 17 | 7 | 8 | 10.5 | 0.2 | 1.27 | 0.82 | 1.3 |

| LFR50/8KDD | 24 | 6 | 8 | 24 | 11 | 11 | 14 | 0.3 | 3.67 | 2.28 | 1.3 |

| LFR50/8NPP | 24 | 6 | 8 | 24 | 11 | 11 | 14 | 0.3 | 3.67 | 2.28 | 1.3 |

| LFR50/8-8KDD | 24 | 8 | 8 | 24 | 11 | 11 | 14.75 | 0.3 | 3.67 | 2.28 | 1.3 |

| LFR50/8-8NPP | 24 | 8 | 8 | 24 | 11 | 11 | 14.75 | 0.3 | 3.67 | 2.28 | 1.3 |

| LFR30/8KDD | 31 | 10 | 8 | 26.8 | 11 | 13 | 16.7 | 0.3 | 3.67 | 2.28 | 1.3 |

| LFR30/8NPP | 31 | 10 | 8 | 26.8 | 11 | 13 | 16.7 | 0.3 | 3.67 | 2.28 | 1.3 |

| LFR5201KDD | 68 | 10 | 12 | 35 | 15.9 | 15.9 | 20.65 | 0.3 | 8.5 | 5.1 | 5.1 |

| LFR5201NPP | 68 | 10 | 12 | 35 | 15.9 | 15.9 | 20.65 | 0.3 | 8.5 | 5.1 | 5.1 |

| LFR5301KDD | 130 | 10 | 12 | 42 | 19 | 19 | 24 | 0.6 | 13 | 7.7 | 7.5 |

| LFR5301NPP | 130 | 10 | 12 | 42 | 19 | 19 | 24 | 0.6 | 13 | 7.7 | 7.5 |

| LFR5301-20KDD | 125 | 20 | 12 | 42 | 19 | 19 | 28 | 0.6 | 13 | 7.7 | 7.5 |

| LFR5301-20NPP | 125 | 20 | 12 | 42 | 19 | 19 | 28 | 0.6 | 13 | 7.7 | 7.5 |

| LFR5302KDD | 163 | 10 | 15 | 47 | 19 | 19 | 26.65 | 1 | 16.2 | 9.2 | 6.2 |

| LFR5302NPP | 163 | 10 | 15 | 47 | 19 | 19 | 26.65 | 1 | 16.2 | 9.2 | 6.2 |

| LFR5201-12KDD | 68 | 12 | 12 | 35 | 15.9 | 15.9 | 21.75 | 0.3 | 8.4 | 5 | 5.1 |

| LFR5201-12NPP | 68 | 12 | 12 | 35 | 15.9 | 15.9 | 21.75 | 0.3 | 8.4 | 5 | 5.1 |

| LFR5201-14KDD | 107 | 14 | 12 | 39.9 | 18 | 20 | 24 | 0.3 | 8.9 | 5 | 6.7 |

| LFR5201-14NPP | 107 | 14 | 12 | 39.9 | 18 | 20 | 24 | 0.3 | 8.9 | 5 | 6.7 |

| LFR5201-10.4KDD | 115 | 10 | 12 | 39.9 | 18 | 20 | 22 | 0.3 | 8.9 | 5 | 6.7 |

| LFR5201-10.4NPP | 115 | 10 | 12 | 39.9 | 18 | 20 | 22 | 0.3 | 8.9 | 5 | 6.7 |

| LFR5204-16KDD | 195 | 16 | 20 | 52 | 20.6 | 22.6 | 31.5 | 0.6 | 16.8 | 9.5 | 12.1 |

| LFR5204-16NPP | 195 | 16 | 20 | 52 | 20.6 | 22.6 | 31.5 | 0.6 | 16.8 | 9.5 | 12.1 |

| LFR5206-20KDD | 435 | 20 | 25 | 72 | 23.8 | 25.8 | 41 | 0.6 | 29.5 | 16.6 | 20.7 |

| LFR5206-20NPP | 435 | 20 | 25 | 72 | 23.8 | 25.8 | 41 | 0.6 | 29.5 | 16.6 | 20.7 |

| LFR5206-25KDD | 425 | 25 | 25 | 72 | 23.8 | 25.8 | 43.5 | 0.6 | 29.5 | 16.4 | 23.1 |

| LFR5206-25NPP | 425 | 25 | 25 | 72 | 23.8 | 25.8 | 43.5 | 0.6 | 29.5 | 16.4 | 23.1 |

| LFR5207-30KDD | 660 | 30 | 30 | 80 | 27 | 29 | 51 | 1 | 38 | 20.8 | 21.4 |

| LFR5207-30NPP | 660 | 30 | 30 | 80 | 27 | 29 | 51 | 1 | 38 | 20.8 | 21.4 |

| LFR5208-40KDD | 1360 | 40 | 40 | 98 | 36 | 38 | 62.5 | 1 | 54.8 | 29 | 55 |

| LFR5208-41KDD | 1360 | 40 | 40 | 98 | 36 | 38 | 62.5 | 1 | 54.8 | 29 | 55 |

| LFR5208-42KDD | 1400 | 50 | 50 | 110 | 44 | 46 | 72.5 | 1.1 | 53 | 39.5 | 69 |

| LFR5208-43KDD | 1400 | 50 | 50 | 110 | 44 | 46 | 72.5 | 1.1 | 53 | 39.5 | 69 |